FINE PITCH WIRE BONDING WEDGES (FP SERIES)

FP Series - Fine Pitch Bonding Tool

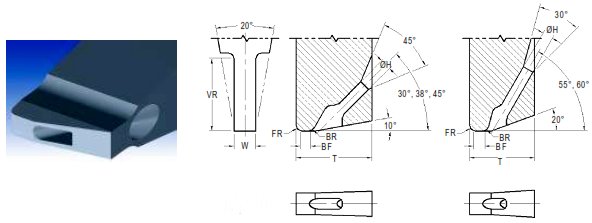

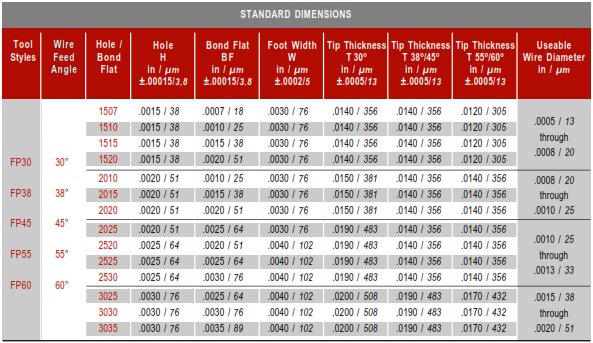

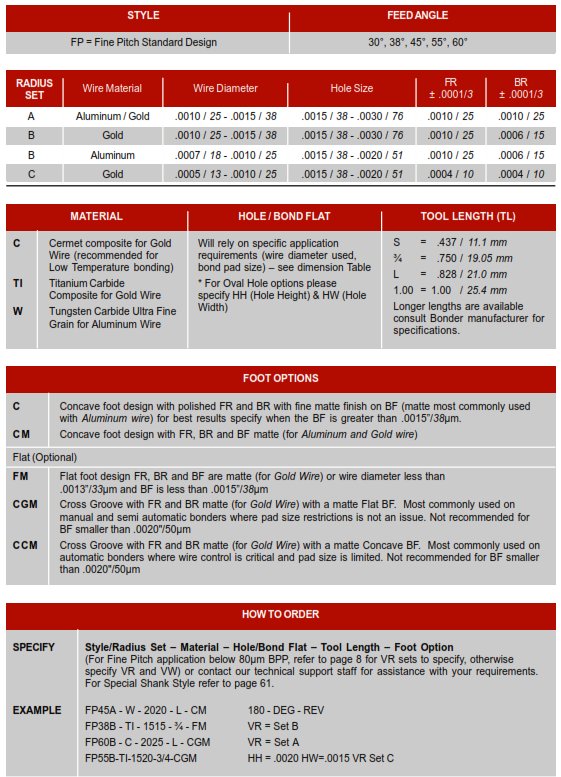

There are a number of technical challenges unique to fine pitch wire-bond process. It includes a broad mix of component technologies. A typical package may contain 200 different components ranging in size from (.008 inch X .008 inch) and .004 inches thick to (.500 inch X .500 inch). The sheer number of different sized chips and tight chip-to-chip spacing create problems in accessing the bond pads. Fine pitch wire-bonding is of particular importance in the manufacturing of these devices. Fine pitch is defined as 100 microns or less center-to-center distances between bond pads. Many devices use the latest high performance chips that typically include 4 mil pitch bond pads. Innovations in tool configurations, machine vision systems and wirebonding ultrasonics have been critical to improved fine pitch wedge bonding. Available in 30°C, 38°C, 45°C, 55°C & 60°C wire feed angles

ORDERING INFORMATION (PLEASE ADVISE REQUIREMENTS & QUANTIY FOR QUOTE OR ASSITANCE)

Part Number - FP Wedge

ORDERING INFORMATION (PLEASE ADVISE REQUIREMENTS & QUANTIY FOR QUOTE OR ASSITANCE)

Part Number - FP Wedge Part Number - VF - Vertical Hole Shank FP Wedge

Part Number - VF - Vertical Hole Shank FP Wedge Part Number - JF - Special Clearance For Vertical Hole Shank FP Wedge

Part Number - JF - Special Clearance For Vertical Hole Shank FP Wedge Part Number - HF - Double Flat Shank FP Wedge

Part Number - HF - Double Flat Shank FP Wedge Part Number - PF - Double Flat Shank - Enhanced Transducer FP Wedge

Part Number - PF - Double Flat Shank - Enhanced Transducer FP Wedge Part Number - FP-180-DEG-REV -180 Degree Reversed Shank Wedge

Part Number - FP-180-DEG-REV -180 Degree Reversed Shank Wedge