Phone: +44 (0)1460 61791 Email: sales@epakelectronics.com

Built to do the job and built to last.

BV9000 Wafer Beveller is designed to produce a pulley wheel bevel on wafers from 30 mm to 150 mm diameter. Designed to integrate Comco Microblasters, the BV9000 is built on a table with self-leveling pneumatic vibration isolation feet supporting the spindle, blast chamber with extract port and incorporating a baffle.

To prevent problems with abrasive wear on the moving parts, there are two positively pressured chambers with doors containing the notch and cut off micrometer assemblies and the motorised stages also have separate positive pressure. The table provides sufficient space for three microblasters and parts. Beneath the bench two cabinets house the control system electrics/electronics and pneumatic and vacuum controls.

The spindle and chuck holding the wafer is designed to run at speeds up to 800 rpm.

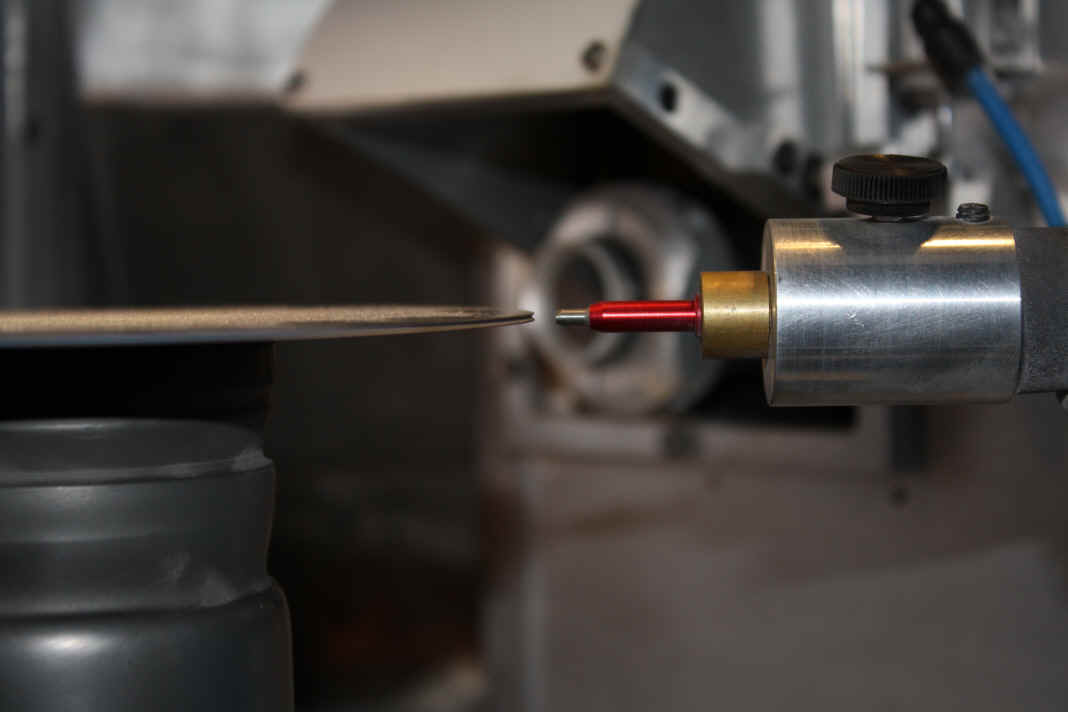

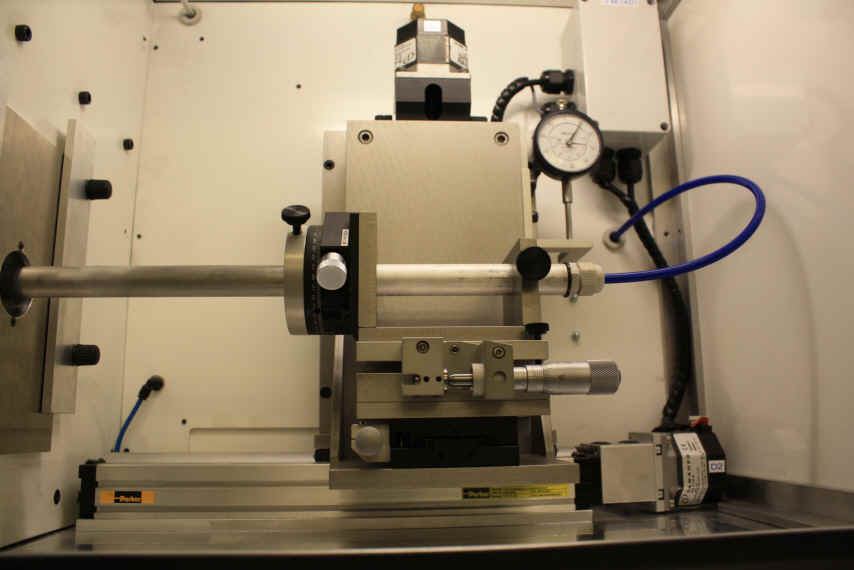

The cut off blast head assembly is retractable for loading and unloading and adjustable in X-axis for position relative to the wafer. The cut off heads are adjustable in X, Y, Z and azimuth. The upper cut off head is motorised in X-axis.

The notch blast head assembly is retractable for loading and unloading and adjustable in X-axis for position relative to the wafer. The notch head is to be adjustable in Y, Z, tilt and rotational theta axis. The notch head to be motorised in Z-axis.

Both notch assembly and cut-off assembly adjustments provide travel, accuracy and repeatability The motorised X & Z stages can move to a repeatable position within 10 microns. Dial gauges allow for a simple, visual display of any adjustments made.

Two (2) camera and lens assemblies allow wafer centering and monitoring of the notch edge cutting process. The digital images are displayed on an LCD monitor.

Control system and user panel feature controls to allow ease of operation and repeatability of the process.

A video overlay generator provides alignment marks on the screen for checking the desired profile and for wafer centering.

The BV9000 allows easy integration for the new Comco Accuflo for even greater precision and blast performance.

Please contact us if you have a custom or automation requirement.

See here for our custom equipment gallery.

ABRASIVE MICROBLASTERS ABRASIVE MICROBLASTERS

|

EPAK CUSTOM EQUIPMENT EPAK CUSTOM EQUIPMENT

|

|---|

Solderability Test Equipment

Anthem Lead Dipping Equipment

Odyssey Lead Dipping System

Dynamic & Static Solder Pots

FRX-10 Economy Selective Soldering

Photon Steam Ager

Solderability Test Equipment

Anthem Lead Dipping Equipment

Odyssey Lead Dipping System

Dynamic & Static Solder Pots

FRX-10 Economy Selective Soldering

Photon Steam Ager

© 2014 All rights reserved. | Design by TEMPLATED.