QFN Bonding Capillaries from SPT (SQ Series)

As the consumer market aggressively demands for the miniaturization of electronic products with more functionality, the requirement for small IC components has significantly increased, particularly on QFN packaging. Two major advantages of QFN over other leaded packages are - cost to manufacturer (for small, thinner, lighter in size, hence promoting more units per lead frame) and improved performance ICs (for better thermal dissipation and reduction in lead inductance).

In general, QFN packages are available in two types - a punch type and a sawn type. A sawn type typically comes with a polyimide tape before die attach or wire bond process. The purpose of the tape is to prevent the bleeding of the resin from the moulding compound into the backside of the QFN leadframe. However, the polyimide tape causes the lead to bounce when exposed to high temperature coming from the heater block.

As the consumer market aggressively demands for the miniaturization of electronic products with more functionality, the requirement for small IC components has significantly increased, particularly on QFN packaging. Two major advantages of QFN over other leaded packages are - cost to manufacturer (for small, thinner, lighter in size, hence promoting more units per lead frame) and improved performance ICs (for better thermal dissipation and reduction in lead inductance).

In general, QFN packages are available in two types - a punch type and a sawn type. A sawn type typically comes with a polyimide tape before die attach or wire bond process. The purpose of the tape is to prevent the bleeding of the resin from the moulding compound into the backside of the QFN leadframe. However, the polyimide tape causes the lead to bounce when exposed to high temperature coming from the heater block.

Challenges of Bonding QFN

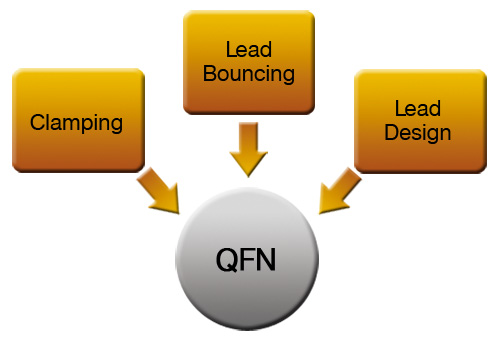

QFN wire bonding has its own special characteristics as compared with other leaded packages. Looking at the wire bond process set up, QFN is much more complicated than other packages and these are highly influenced by the clamping, lead bouncing and lead design.

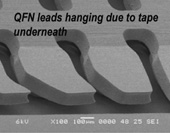

The QFN package tie bar width and thickness design greatly affect the wire bonding performance. Wider and thicker lead configuration are preferred as this will have lower reaction towards leads bouncing during the wire bonding process. Lead bouncing is more prominent on tape QFN where the tape actually “softens” when subjected to high bonding temperature of equal or more than 200˚C. The “softening” effect will absorb certain amount of USG power needed for a better weld of the wire to the lead surface to form the stitch.

Challenges of Bonding QFN

QFN wire bonding has its own special characteristics as compared with other leaded packages. Looking at the wire bond process set up, QFN is much more complicated than other packages and these are highly influenced by the clamping, lead bouncing and lead design.

The QFN package tie bar width and thickness design greatly affect the wire bonding performance. Wider and thicker lead configuration are preferred as this will have lower reaction towards leads bouncing during the wire bonding process. Lead bouncing is more prominent on tape QFN where the tape actually “softens” when subjected to high bonding temperature of equal or more than 200˚C. The “softening” effect will absorb certain amount of USG power needed for a better weld of the wire to the lead surface to form the stitch.

The effect of QFN matrix leadframe made it impossible to design a clamping system which will hold the middle fingers at the centre of the bonding area

(Figure 2). Under this condition, the best way to clamp or hold QFN matrix leadframe would be around its perimeter. Consequently, this leaves the middle of the QFN matrix leadframe area prone to micro bouncing. The micro-bouncing effect will always be inherent with the QFN bonding (with tape underneath), causing some instability issue in second bond deformation.

In a typical stitch bonding (second bond) process, the use of lesser USG power setting is more preferred for QFN with tape underneath. This is to minimize the micro bouncing effect translated to the ball bond (first bond) causing ball neck stress or damage.

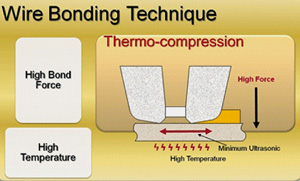

The introduction of thermocompression (a combination of force & temperature - Figure 4) - alleviates micro-bouncing effect on the QFN matrix leadframe, resolving ball neck stress or damage. Usually, a longer bonding time of more than 15 milliseconds with high and gradually ramping up bond force profile, ranging from more than 100g to less than 500g (depending on wire size) are pre-requisites for good thermocompression bonding. The introduction of thermocompression bonding reduces the effect of the micro bouncing providing better quality bonding and smoother bonding performance that are necessary in mass volume production environment.

The effect of QFN matrix leadframe made it impossible to design a clamping system which will hold the middle fingers at the centre of the bonding area

(Figure 2). Under this condition, the best way to clamp or hold QFN matrix leadframe would be around its perimeter. Consequently, this leaves the middle of the QFN matrix leadframe area prone to micro bouncing. The micro-bouncing effect will always be inherent with the QFN bonding (with tape underneath), causing some instability issue in second bond deformation.

In a typical stitch bonding (second bond) process, the use of lesser USG power setting is more preferred for QFN with tape underneath. This is to minimize the micro bouncing effect translated to the ball bond (first bond) causing ball neck stress or damage.

The introduction of thermocompression (a combination of force & temperature - Figure 4) - alleviates micro-bouncing effect on the QFN matrix leadframe, resolving ball neck stress or damage. Usually, a longer bonding time of more than 15 milliseconds with high and gradually ramping up bond force profile, ranging from more than 100g to less than 500g (depending on wire size) are pre-requisites for good thermocompression bonding. The introduction of thermocompression bonding reduces the effect of the micro bouncing providing better quality bonding and smoother bonding performance that are necessary in mass volume production environment.

Figure 4: Use of thermocompression in QFN

What is SPT’s new SQ capillary?

SPT’s new SQ capillary series features a consistent surface morphology finishing used for both gold (Au) and copper (Cu) wires, specifically developed for QFN wire bonding. The SQ capillary is designed in line with thermocompression bonding concept. The uniqueness of the SQ capillary is shown in the actual bonding response in terms of higher productivity (due to improved MTBA & higher capillary touchdown) and reliability of the bonded product.

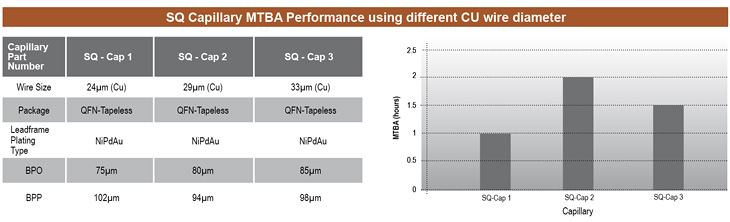

Improved MTBA

Figure 4: Use of thermocompression in QFN

What is SPT’s new SQ capillary?

SPT’s new SQ capillary series features a consistent surface morphology finishing used for both gold (Au) and copper (Cu) wires, specifically developed for QFN wire bonding. The SQ capillary is designed in line with thermocompression bonding concept. The uniqueness of the SQ capillary is shown in the actual bonding response in terms of higher productivity (due to improved MTBA & higher capillary touchdown) and reliability of the bonded product.

Improved MTBA

With SQ capillary, there will be lesser assist due to short tail or broken stitch which is inherent with bonding QFN package. Experience more machine uptime!

Higher Capillary Touchdown

With SQ capillary, there will be lesser assist due to short tail or broken stitch which is inherent with bonding QFN package. Experience more machine uptime!

Higher Capillary Touchdown

SQ capillary coupled with optimized bonding parameters, has proven to deliver an increase in the capillary tool life as lower bond force (BF) is utilized to bond the QFN package.

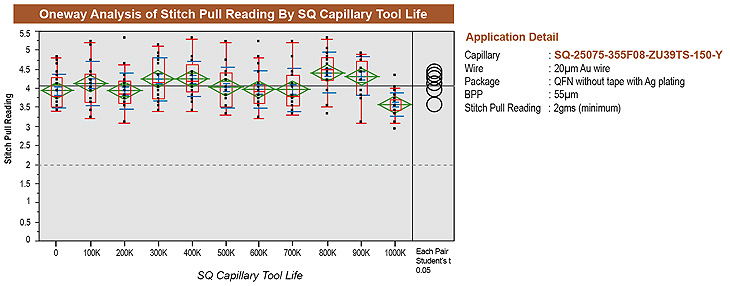

Proven Reliability

Whether on gold or copper wire, the SQ capillary is designed to enhance the formation of larger & width stitch bond that will effectively increase the stitch pull reading values & longer size copper remains.

SQ capillary coupled with optimized bonding parameters, has proven to deliver an increase in the capillary tool life as lower bond force (BF) is utilized to bond the QFN package.

Proven Reliability

Whether on gold or copper wire, the SQ capillary is designed to enhance the formation of larger & width stitch bond that will effectively increase the stitch pull reading values & longer size copper remains.

Popular Designs For Copper |

||||||

| Bond Pad Pitch µm |

Useable Wire Diameter µm |

H µm |

CD µm |

FA ° |

T µm |

Recommended SPT Part Number |

| 50 | 20 | 25 | 30 | 11 | 63 | SQ-25063-305F-ZU39TS |

| 60 | 23 | 28 | 35 | 11 | 80 | SQ-28080-355F-ZU39TS |

| 60 | 25 | 30 | 38 | 11 | 80 | SQ-30080-385F-ZU39TS |

| 70 | 25 | 33 | 43 | 8 | 90 | SQ-33090-435E-ZU39TS |

| 80 | 25 | 33 | 48 | 8 | 100 | SQ-33100-485E-ZU39TS |

| 80 | 30 | 38 | 51 | 8 | 100 | SQ-38100-515E-ZU39TS |

| 90 | 25 | 35 | 51 | 8 | 110 | SQ-35110-515E-ZU39TS |

| 90 | 30 | 38 | 53 | 8 | 110 | SQ-38110-535E-ZU39TS |

| 100 | 30 | 38 | 55 | 8 | 130 | SQ-38130-555E-ZU39TS |

| 110 | 33 | 41 | 58 | 8 | 165 | SQ-41165-585E-ZU39TS |

|

||||||

| Bond Pad Pitch µm |

Useable Wire Diameter µm |

H µm |

CD µm |

FA ° |

T µm |

Recommended SPT Part Number |

| 50 | 20 | 25 | 30 | 11 | 63 | SQ-25063-305F-ZS39TS |

| 60 | 23 | 28 | 35 | 11 | 80 | SQ-28080-355F-ZS39TS |

| 60 | 25 | 30 | 38 | 11 | 80 | SQ-30080-385F-ZS39TS |

| 70 | 25 | 33 | 43 | 8 | 90 | SQ-33090-435E-ZS39TS |

| 80 | 25 | 33 | 48 | 8 | 100 | SQ-33100-485E-ZS39TS |

| 80 | 30 | 38 | 51 | 8 | 100 | SQ-38100-515E-ZS39TS |

| 90 | 25 | 35 | 51 | 8 | 110 | SQ-35110-515E-ZS39TS |

| 90 | 30 | 38 | 53 | 8 | 110 | SQ-38110-535E-ZS39TS |

| 100 | 30 | 38 | 55 | 8 | 130 | SQ-38130-555E-ZS39TS |

| 110 | 33 | 41 | 58 | 8 | 165 | SQ-41165-585E-ZS39TS |

Capillary Part Number Selection Guide

The capillary design selection guide is always based on specific device & package configuration, wire type, and wire bonder. The selection of capillary part number process is simplified as follows: Capillary Tip The selection of capillary tip design is determined by the device and metallization, bond pad pitch, bond pad opening, wire size, target mashed ball diameter, and critical loop height to derive the hole diameter(HD), chamfer diameter (CD), chamfer angle (CA), tip diameter (T) and face angle (FA). Shank Style The shank style selection is characterized by geometrical design of the capillary bonding tool as dictated by specific device and / or package configuration. Surface Finish The selection of a particular capillary tip surface finish hinges on whether the application is for gold or copper wire bonding. Material Capillary material selection for optimum tool life performance for a given bonding application. Wire Type The proper selection of capillary design is a resultant of the various wire bonding considerations.Infinity 3X Longer Tool Life

SPT 'Infinity' capillary material extends the tool life up to 3X its original tool life. This option is available on many tools and is a proprietary process SPT use to increase tool life.ORDERING INFORMATION (PLEASE ADVISE REQUIREMENTS & QUANTIY FOR QUOTE OR ASSITANCE) Part Number - SQ Series QFN Wire Bonding Capillaries