Phone: +44 (0)1460 61791 Email: sales@epakelectronics.com

The CON-TROL-CURE® CROSS CUT TESTER contains all the tools and materials needed for conducting adhesion tests on inks and coatings applied to a flat, uniform surface.

KIT CONTAINS: • Multiple tip cutter in a formed handle with nylon protector and guide • 1 Medium Blade with 1.5 mm spacing, Eleven Teeth standard - other blades available by request or can be purchased separately • Hex wrench for changing blades • Flaking brush • Illuminated magnifier with batteries • 72 yards (216 ft) of *LA-26 tape • Copy of ASTM Test Method D-3359 as an instruction guide • Plastic case with handle

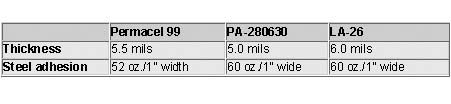

*Permacel tape #99 was discontinued by the manufacturer. Therefore the tape in the kit is no longer Permacel #99 it is currently PA-280630. Both PA-280630 and LA-26 are potential substitutes that are being evaluated by ASTM. We are selling PA-280630 until ASTM makes an official selection for the revision of ASTM D3359 "Measuring Adhesion by Tape Test"

Spares:

Part Number - N002-006 Adhesion Flaking Brush

Spares:

Part Number - N002-006 Adhesion Flaking Brush Part Number - N002-014 Blade Handle

Part Number - N002-014 Blade Handle Part Number - N004-002 Cross Cut 1mm Blade

Part Number - N004-002 Cross Cut 1mm Blade Part Number - N004-013 Adhesion 11T 1.5mm

Part Number - N004-013 Adhesion 11T 1.5mm Part Number - N004-014 Adhesion 6T 2mm Spacing

Part Number - N004-014 Adhesion 6T 2mm Spacing Part Number - N004-015 Adhesion 6T 3mm Spacing

Part Number - N004-015 Adhesion 6T 3mm Spacing Part Number - N004-018B PA-28063 Tape

Part Number - N004-018B PA-28063 Tape

Densitometers & Spectrodensitometers

Ink Thickness Controls

Ink Testing & Measurement

60 Degree Glossmeter

Surface Tension Measurement

Flexographic Hand Proofers

Ink and Film Thickness Controls

Permeability Cup

Densitometers & Spectrodensitometers

Ink Thickness Controls

Ink Testing & Measurement

60 Degree Glossmeter

Surface Tension Measurement

Flexographic Hand Proofers

Ink and Film Thickness Controls

Permeability Cup

8 Path Scraper

Blade Applicator Gauge

Drawdown Rods and Bars

Handheld Drawdown

Laboratory Drawdown

Mini-Laboratory Drawdown

Drawdown Bar Storage Rack

8 Path Scraper

Blade Applicator Gauge

Drawdown Rods and Bars

Handheld Drawdown

Laboratory Drawdown

Mini-Laboratory Drawdown

Drawdown Bar Storage Rack

© 2014 All rights reserved. | Design by TEMPLATED.